Delving into the Intricacies of a 10 kW Lever Engine

An Overview of Lever Engines and Energy Production

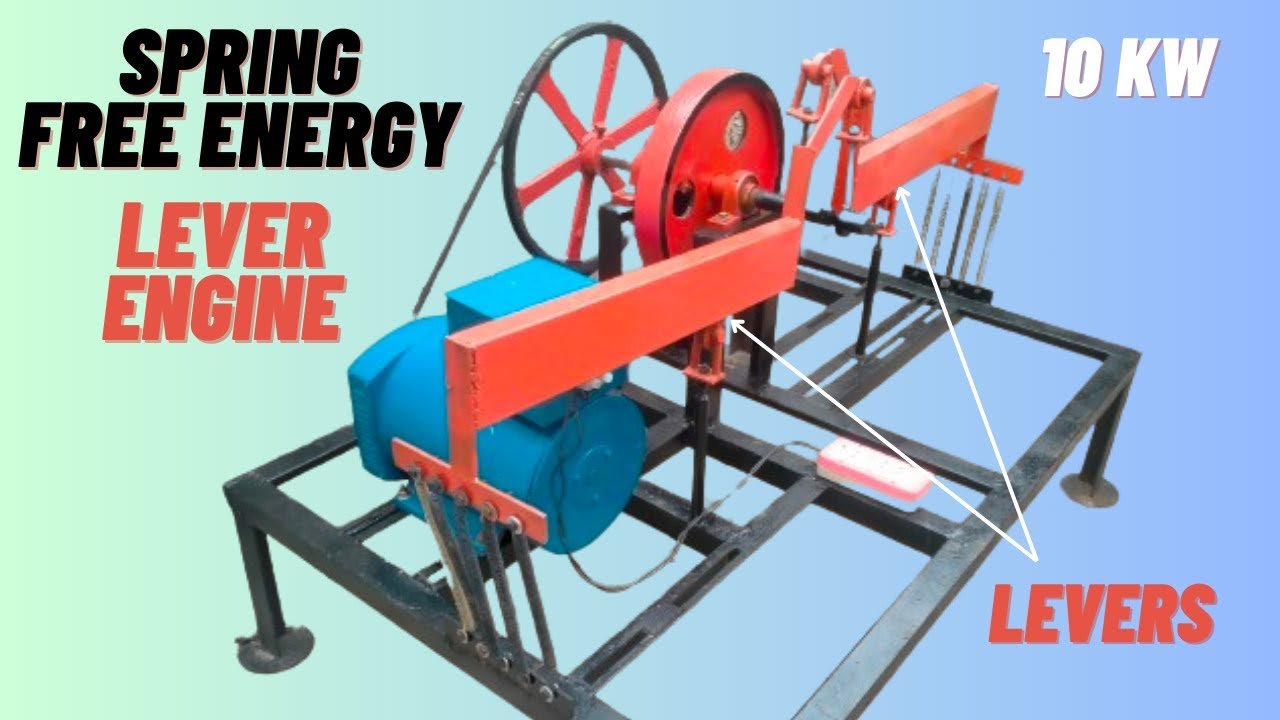

Lever Engine -based energy apparatuses, often touted as potential “free-energy” contraptions, encompass systems of mechanical elements—such as levers, springs, gears, and weights—engineered to transform mechanical movement into utilizable energy. The notion of a self-perpetuating, continuous power source is captivating, but in actuality, such machines grapple with considerable physical constraints. This section probes into the theoretical configuration of a “10 kW Lever Engine” and scrutinizes the principles that underscore its functionality, limitations, and why a genuinely self-operating engine remains elusive due to physical laws.

The Power Generation Potential of Lever Engine-Based Systems

Lever engines theoretically aspire to capture energy by leveraging force. A lever magnifies an input force to yield a larger output force, which can theoretically propel a generator, supplying electrical power. In numerous small-scale experiments, enthusiasts utilize weights to tug levers in specific cycles, with each cycle designed to exert a force onto an attached generator, which could generate electricity. This energy could be conserved in a battery for future use, with energy production potentially amplified by optimizing lever length, weight distribution, and cycle timing.

For instance, if a lever system could operate consistently with minimal energy loss, and if it were capable of cycling numerous times per minute, one could theoretically establish a continuous power source. However, producing substantial power—particularly at the scale of 10 kW—would necessitate an exceptionally efficient design, with precise engineering and materials capable of reducing losses due to friction, heat, and inefficiency.

Key Components of a Lever Engine

Constructing a lever Engine-based energy system necessitates several fundamental components:

The Lever and Fulcrum: A lever system, ideally balanced on a low-friction fulcrum, would magnify input energy. A long, robust lever with appropriate fulcrum placement could transform small inputs into larger outputs, though the lever must be of high-strength material to withstand the stresses involved in power generation.

Springs or Counterweights: Springs could be wound or weights hoisted as part of a cyclic mechanism to augment energy storage capacity. Springs discharge stored energy when released, and weights descend, converting potential energy into kinetic energy. These components would necessitate a system to reset or rewind them, likely requiring external energy input.

Gears and Flywheels: To enhance the output speed or torque of the lever system, gears and flywheels could be incorporated. A gear train would assist in stepping up the rotation speed to align with the generator requirements, while a flywheel could conserve rotational energy and stabilize fluctuations in power output.

Electrical Generator: The lever system’s motion must ultimately propel a generator to transform mechanical energy into electrical energy. For a DIY setup, a permanent magnet DC generator is often employed due to its simplicity and efficiency. The generator would need to be matched to the lever’s motion to ensure effective energy transfer.

Control System: To sustain and optimize energy production, a control system could be implemented. This system would supervise the cycle timing, energy storage, and release process, and manage any resetting requirements for the lever or spring mechanism. This can involve basic electronics or mechanical timers in DIY applications.

Addressing the Limitations and Energy Losses

While the setup above delineates a plausible approach to generating power, constructing a 10 kW lever engine confronts substantial hurdles rooted in the laws of thermodynamics. Here are some key limitations:

Energy Input vs. Output: For the system to be “free-running,” it would need to generate more energy than it consumes. However, every mechanical system incurs some energy losses due to friction (in gears, bearings, and the fulcrum), air resistance, and heat. These losses are typically small but accumulate, meaning the engine would eventually decelerate without an external energy source.

Thermodynamic Limits: According to the law of conservation of energy, energy cannot be created from nothing. The energy produced by a lever engine originates directly from the force applied to it initially. Over time, without a new input of energy, the device would lose power and eventually halt. Devices like springs can store energy for short-term use, but they still need periodic winding, an input that contradicts the concept of “free energy.”

Maintenance and Mechanical Degradation: In DIY setups, maintenance is a significant consideration. The constant motion of levers, springs, and gears will lead to wear and tear. Over time, these components degrade, increasing energy losses due to friction and reducing efficiency. Creating a machine that maintains high output over a long period without maintenance would require high-grade materials and precise engineering, adding cost and complexity.

Scaling to 10 kW: For comparison, small home solar installations typically produce around 5-10 kW of power, but they do so by directly capturing energy from sunlight, an external source. A lever engine would have to convert small, mechanically stored energy cycles into sustained, large-scale output, which is exceedingly challenging without continuous energy replenishment.

Alternative Approaches: Feasible DIY Energy Projects

Though self-operating lever engines aren’t viable indefinitely, there are other practical DIY energy sources that are attainable with meticulous planning and construction:

Wind Turbines: DIY wind turbines transform wind energy into electricity and can generate significant power under windy conditions. Using a permanent magnet generator, blades made from lightweight material, and a gear system, hobbyists can create efficient small-scale wind turbines capable of supplementing household energy needs.

Solar Panels and Solar Trackers: Solar panels are extensively used for DIY energy projects, harnessing sunlight to generate electricity without moving parts. Adding a DIY solar tracker, which adjusts panel angles for maximum sunlight capture, can enhance efficiency.

Bicycle Generators: Another option is a stationary bike attached to a generator. This system allows for short-term energy generation using mechanical energy, which can be used to charge batteries. While it requires human input, it’s a straightforward way to convert motion to electricity for small tasks.

Hydropower Systems: In areas with access to flowing water, DIY hydropower setups can generate continuous power. Small turbines placed in streams or rivers convert water flow into electricity. Hydropower can be a reliable and renewable energy source where suitable water sources exist.

Conclusion: The Quest for Practical Energy Solutions

While the dream of a self-sustaining 10 kW lever engine is compelling, current technology and the laws of physics present insurmountable barriers to achieving truly “free” energy. Energy input is always necessary to sustain power output, and any mechanical system will gradually lose energy due to unavoidable factors like friction and resistance. Nevertheless, DIY enthusiasts can explore numerous practical, renewable energy projects that leverage natural forces—wind, sunlight, and water—to generate sustainable power for small-scale applications. With continued advancements in energy storage and efficiency, these systems can provide meaningful contributions to home energy needs and serve as educational, inspiring projects for those interested in renewable energy.