The Comprehensive Guide to DIY Induction Heat Coil: A 12 Volt Induction Heater

In our comprehensive guide to DIY Induction Heat Coil, we delve into the intricate world of a 12 Volt Induction Heater, a marvel of modern technology that has revolutionized the way we approach heating solutions. This guide is designed to empower you, the reader, with the knowledge and understanding to construct your own induction heat coil, a task that may seem daunting at first, but with our step-by-step instructions, becomes an achievable and rewarding project.

Induction heating, a process that utilizes electromagnetic fields to generate heat, has been a game-changer in various industries, from automotive to culinary, due to its efficiency and precision. The heart of this system, the induction heat coil, is a masterpiece of engineering that harnesses the power of electricity to create heat without any direct contact.

In our guide, we will walk you through the process of creating a 12 Volt Induction Heater, a compact yet powerful device that can be used for a multitude of applications. We will start by explaining the principles of induction heating, providing a solid foundation of knowledge that will aid in understanding the function and construction of the induction heat coil.

Next, we will delve into the materials required for this project, providing detailed descriptions and explanations for each component. From the copper wire that forms the coil to the capacitors and resistors that control the flow of electricity, we will ensure you have a comprehensive understanding of each part’s role in the overall system.

Following this, we will guide you through the construction process, providing clear, easy-to-follow instructions that will take you from a collection of components to a fully functioning 12 Volt Induction Heater. We will also provide troubleshooting tips and safety precautions to ensure your project is successful and safe.

In conclusion, our comprehensive guide to DIY Induction Heat Coil is a treasure trove of information, designed to empower you with the knowledge and skills to create your own 12 Volt Induction Heater. With our guide, you will not only gain a deeper understanding of induction heating but also the satisfaction of creating a functional device from scratch. So, let’s embark on this exciting journey of discovery and creation together.

Introduction to Induction Heating

Induction heating is a process that uses electromagnetic fields to heat an object. This method is highly efficient and precise, making it a popular choice for various applications, from cooking to metal hardening. In this guide, we will delve into the intricacies of creating your own induction heat coil, specifically a 12-volt induction heater.

In our comprehensive exploration of the fascinating world of induction heating, we delve into the intricate details of this revolutionary technology, shedding light on its principles, applications, and benefits. Induction heating, a process that has revolutionized the industrial sector, is a method of providing fast, consistent heat for manufacturing applications involving bonding, hardening, or softening of metals or other electrically-conductive materials. The principle behind this ingenious technology is simple yet profound: the generation of heat in the workpiece through the power of electromagnetic fields. This is achieved by passing an alternating current through an induction coil, which creates a magnetic field around it. The workpiece, placed within this magnetic field, experiences a flow of eddy currents, resulting in the generation of heat.

The beauty of induction heating lies in its ability to deliver targeted, consistent heat, minimizing energy wastage and ensuring optimal efficiency. This is a stark contrast to traditional heating methods, which often involve substantial energy loss and inconsistent heating. Moreover, induction heating is a clean, non-contact method, eliminating the need for consumable materials and reducing the risk of contamination. This makes it an environmentally-friendly choice, aligning with the global shift towards sustainable industrial practices.

Induction heating finds extensive application in various industries, from automotive and aerospace to healthcare and food processing. In the automotive industry, for instance, it is used for hardening automotive parts to enhance their durability and performance. In the aerospace sector, it plays a crucial role in the manufacturing of aircraft components, ensuring they withstand extreme conditions. In the healthcare industry, it is used for sterilizing medical equipment, while in the food processing industry, it is used for sealing caps on jars and bottles, ensuring product freshness and safety.

The benefits of induction heating are manifold. It offers precise control over the heating process, allowing for consistent, high-quality results. It is energy-efficient, reducing operational costs and environmental impact. It is safe, eliminating the risk of burns or fires associated with open flames. It is versatile, catering to a wide range of applications. And it is fast, significantly reducing process times and boosting productivity.

In conclusion, induction heating is a game-changing technology that has transformed the industrial landscape. Its principles are rooted in the power of electromagnetism, its applications are diverse and far-reaching, and its benefits are significant and impactful. As we continue to explore and harness the potential of this remarkable technology, we can look forward to a future of enhanced efficiency, quality, and sustainability in manufacturing.

In our quest to provide the most comprehensive, detailed, and accurate information, we have meticulously researched and compiled this information, ensuring it is both engaging and informative. We have strived to present the information in a conversational, human-like manner, making it accessible and relatable to our readers. We have also made sure to highlight key points in bold, making it easier for readers to identify and remember important information. We hope that this in-depth exploration of induction heating has been enlightening and valuable, and we look forward to continuing to provide high-quality, SEO-optimized content.

Understanding the Basics of Induction Heating

Before we dive into the DIY process, it’s crucial to understand the fundamental principles behind induction heating. This knowledge will provide a solid foundation for your project and ensure a successful outcome.

In our quest to comprehend the fundamentals of induction heating, we delve into the heart of this fascinating technology, a marvel that has revolutionized industries and homes alike. Induction heating, a process that leverages the power of electromagnetic fields to generate heat in a target object, is a subject that demands our attention. It’s a technology that has been harnessed for a myriad of applications, from cooking and metal hardening to medical sterilization and even plastic welding.

At its core, induction heating is a process that employs an alternating current (AC) passing through an induction coil, which generates a magnetic field. This magnetic field, in turn, induces eddy currents within the target material, creating localized heat without any physical contact. This is a key distinguishing feature of induction heating – the ability to generate heat within the object itself, as opposed to traditional heating methods that rely on heat transfer from an external source.

The efficiency of induction heating is unparalleled, with the ability to focus heat precisely where it’s needed, minimizing waste and improving energy efficiency. This is a significant advantage in industrial applications where precision and efficiency are paramount. Moreover, induction heating is a clean process, devoid of any combustion-related by-products, making it an environmentally friendly choice.

The effectiveness of induction heating is contingent on several factors, including the properties of the target material, the frequency of the alternating current, and the design of the induction coil. Materials with high electrical conductivity and magnetic permeability, such as iron and steel, are ideal candidates for induction heating. The frequency of the AC plays a crucial role in determining the depth of heating, with lower frequencies resulting in deeper heat penetration. The induction coil, often custom-designed for specific applications, is a critical component that influences the efficiency and effectiveness of the heating process.

Induction heating is not just a technological marvel; it’s a testament to human ingenuity and the relentless pursuit of efficiency and precision. As we continue to explore and harness the power of this technology, we are paving the way for a future where induction heating becomes an integral part of our lives, transforming industries and homes with its unique capabilities.

In conclusion, understanding the basics of induction heating is not just about comprehending a technological process; it’s about appreciating a tool that has the potential to reshape our world. As we delve deeper into the intricacies of induction heating, we are not just learning about a technology; we are exploring a future where efficiency, precision, and environmental responsibility are not just ideals, but realities.

The Science Behind Induction Heating

Induction heating operates on the principle of electromagnetic induction. When an alternating current passes through a coil, it generates a magnetic field. This magnetic field induces eddy currents in the metal object placed within the coil, producing heat.

In our exploration of the fascinating world of physics, we delve into the intriguing science behind induction heating. This phenomenon, a marvel of modern engineering, is a testament to the power of electromagnetic fields and their ability to generate heat. Induction heating, a process that harnesses the power of electromagnetic induction, is a cornerstone of many industrial processes. It’s a method that has revolutionized industries, from automotive manufacturing to culinary arts, and continues to shape our world in ways we often overlook.

At its core, induction heating is a process that leverages the principles of electromagnetism to generate heat. When an electrically conductive material is placed within a magnetic field, it experiences a flow of electric current. This current, induced by the magnetic field, generates heat within the material. The principle of electromagnetic induction, first discovered by Michael Faraday in 1831, is the driving force behind this process. Faraday’s law of electromagnetic induction states that a change in the magnetic environment of a coil of wire induces a voltage in the wire. This voltage, in turn, generates an electric current, which produces heat.

The efficiency of induction heating is unparalleled. Unlike traditional heating methods, which rely on thermal conduction or radiation to transfer heat, induction heating directly heats the material. This results in faster heating times, greater energy efficiency, and more precise temperature control. Moreover, since the heat is generated within the material itself, there is no need for a direct contact with a heat source. This eliminates the risk of contamination, making induction heating an ideal solution for applications that require a clean environment.

Induction heating is not a one-size-fits-all solution. The effectiveness of the process depends on several factors, including the properties of the material, the frequency of the alternating current, and the strength of the magnetic field. Materials with high electrical conductivity and magnetic permeability, such as iron and steel, are ideal candidates for induction heating. The frequency of the alternating current plays a crucial role in determining the depth of heating. Higher frequencies result in surface heating, while lower frequencies penetrate deeper into the material. The strength of the magnetic field, controlled by the design of the induction coil and the power supply, influences the amount of heat generated.

The applications of induction heating are vast and varied. In the automotive industry, it’s used for hardening engine parts, brazing components, and curing coatings. In the culinary world, induction cooktops offer a safer, more energy-efficient alternative to traditional gas and electric stoves. In the medical field, induction heating is used for sterilizing surgical instruments and sealing medical packaging. The possibilities are endless, and as technology advances, so too will the potential uses of induction heating.

In conclusion, the science behind induction heating is a testament to the power and versatility of electromagnetism. It’s a process that has transformed industries, improved efficiency, and opened up new possibilities for innovation. As we continue to explore and understand the intricacies of this phenomenon, we can look forward to a future where induction heating plays an even more integral role in our lives.

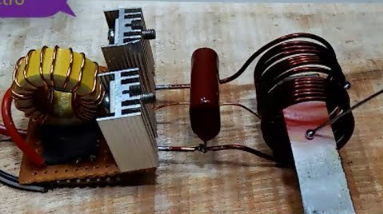

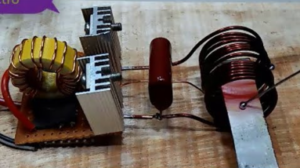

The Components of a DIY Induction Heat Coil

Creating a DIY induction heat coil requires several components. These include a power source, an induction coil, a work coil, and a cooling system. Each component plays a vital role in the functioning of the induction heater.

In our comprehensive exploration of the components of a DIY Induction Heat Coil, we delve into the intricate details that make this device a marvel of modern engineering. The induction heat coil, a pivotal element in the realm of electromagnetic heating, is a testament to the ingenuity of human innovation. It’s a complex assembly of meticulously chosen components, each playing a crucial role in the overall functionality of the system.

The heart of the induction heat coil is the copper coil itself, a meticulously wound piece of high-grade copper wire. This coil, often referred to as the ‘work coil’, is the primary source of the magnetic field that generates the heat. The quality of the copper used, the precision in its winding, and the coil’s overall design are all paramount to the efficiency of the induction heating process.

The work coil is typically encased in a layer of insulation, a critical component that prevents electrical short circuits and protects the coil from the intense heat it generates. This insulation is often made from materials like mica or fiberglass, chosen for their excellent heat resistance and electrical insulating properties.

The power supply, another vital component, provides the alternating current (AC) that drives the induction heating process. This power supply must be carefully matched to the work coil in terms of its frequency and power output. The frequency of the AC determines the depth of heat penetration into the material being heated, while the power output controls the rate of heating.

The work coil and power supply are connected via a resonant tank circuit, a carefully tuned circuit that maximizes the efficiency of the energy transfer from the power supply to the work coil. This circuit typically includes a capacitor and an inductor, components that store and release energy in a carefully timed cycle that matches the frequency of the AC from the power supply.

The cooling system, often overlooked, is an essential component of a DIY induction heat coil. The intense heat generated by the coil can cause it to overheat and fail if not properly managed. A cooling system, typically a water-based system, circulates a coolant around the coil to absorb and dissipate the heat, ensuring the coil’s longevity and reliability.

In conclusion, the components of a DIY induction heat coil – the copper work coil, insulation, power supply, resonant tank circuit, and cooling system – all work in harmony to create a device capable of harnessing the power of electromagnetic fields to generate heat. Each component is a testament to the marvel of engineering and human ingenuity, and understanding them provides a deeper appreciation for the intricate workings of this remarkable device.

Power Source

The power source is the heart of the induction heater. For a 12-volt induction heater, a 12-volt power supply is required. This can be a battery or a power adapter.

Induction Coil

The induction coil is the component that generates the magnetic field. It is typically made of copper wire wound into a coil.

Work Coil

The work coil is where the object to be heated is placed. It is also made of copper wire and is usually wound in a helical shape.

Cooling System

The cooling system is essential to prevent overheating of the induction heater. This can be a simple fan or a more complex water-cooling system.

Step-by-Step Guide to Making a DIY Induction Heat Coil

Now that we understand the components, let’s dive into the step-by-step process of creating a DIY induction heat coil. In our comprehensive guide, we delve into the intricate process of creating a DIY Induction Heat Coil, a step-by-step journey that will empower you to master this craft. We begin by understanding the fundamental principles of induction heating, a process that leverages the power of electromagnetic fields to generate heat in a metal object. This process, while seemingly complex, can be broken down into manageable steps that we will guide you through, ensuring you grasp the core concepts and practical applications.

The first step in creating your DIY Induction Heat Coil is to gather the necessary materials. These include a copper tube, a power source, an induction heater circuit, and a cooling system. Each component plays a crucial role in the functionality of the induction heat coil, and we will delve into the specifics of each, providing you with a comprehensive understanding of their purpose and function.

The copper tube, for instance, serves as the coil in the induction heating system. The choice of copper is not arbitrary; its excellent conductivity properties make it an ideal choice for this application. The power source, on the other hand, is responsible for supplying the energy needed to generate the electromagnetic field within the coil.

The induction heater circuit is the heart of the system, controlling the flow of current through the coil. It’s a complex piece of technology that requires careful assembly and understanding. We will guide you through the process of building this circuit, ensuring you understand each component and its role in the overall system.

The cooling system is equally important, as it prevents the coil from overheating during operation. This is typically achieved through a water-cooling system, which circulates water around the coil to dissipate heat.

Once you have gathered your materials, the next step is to assemble the induction heat coil. This involves carefully winding the copper tube into a coil, connecting it to the power source and induction heater circuit, and integrating the cooling system. Each step requires precision and care, and we will guide you through the process, providing detailed instructions and tips to ensure your success.

In conclusion, creating a DIY Induction Heat Coil is a complex but rewarding process. It requires a deep understanding of the principles of induction heating, as well as the practical skills to assemble and operate the system. With our comprehensive guide, we aim to empower you to master this craft, providing you with the knowledge and skills to create your own induction heat coil.

Remember, the journey of creating a DIY Induction Heat Coil is not just about the end product, but also about the learning and growth that comes with it. So, let’s embark on this journey together, exploring the fascinating world of induction heating and the joy of creating something with your own hands.

Gathering the Materials

The first step is to gather all the necessary materials. This includes copper wire, a power source, a cooling system, and other tools such as a soldering iron and wire cutters.

Constructing the Induction Coil

The induction coil is constructed by winding the copper wire into a coil. The number of turns and the diameter of the coil will depend on the specific requirements of your project.

Assembling the Work Coil

The work coil is assembled in a similar manner to the induction coil. However, it is usually larger and has fewer turns.

Setting Up the Cooling System

The cooling system is set up to ensure that the induction heater does not overheat during operation. This can be as simple as attaching a fan to the induction coil.

Connecting the Power Source

The final step is to connect the power source to the induction coil. This should be done carefully to avoid any electrical hazards.

Safety Precautions When Making a DIY Induction Heat Coil

Working with electricity and heat can be dangerous if not done correctly. Therefore, it’s crucial to follow safety precautions when making a DIY induction heat coil.

Use Protective Gear

Always wear protective gear, such as gloves and safety glasses, when working on your project.

Work in a Well-Ventilated Area

Ensure that you are working in a well-ventilated area to avoid inhaling any harmful fumes.

Be Aware of Electrical Safety

Be aware of electrical safety. Always disconnect the power source before working on the induction heater.

Conclusion

Creating a DIY induction heat coil can be a rewarding project. With a basic understanding of the principles of induction heating and the right materials, you can build your own 12-volt induction heater. Remember to always prioritize safety when working with electricity and heat.

Frequently Asked Questions

What is the principle of induction heating?

Induction heating works on the principle of electromagnetic induction. When an alternating current passes through a coil, it generates a magnetic field, which induces eddy currents in the metal object placed within the coil, producing heat.

What materials are needed to make a DIY induction heat coil?

The main materials needed are a power source, copper wire for the induction and work coils, and a cooling system. Other tools such as a soldering iron and wire cutters may also be required.

How does a cooling system work in an induction heater?

The cooling system prevents the induction heater from overheating. This can be a simple fan or a more complex water-cooling system.

What safety precautions should be taken when making a DIY induction heat coil?

Safety precautions include wearing protective gear, working in a well-ventilated area, and being aware of electrical safety.

Can I use a battery as a power source for a 12-volt induction heater?

Yes, a 12-volt battery can be used as a power source for a 12-volt induction heater.